Extending the Lifespan of Cornell Pump Seals

- MySafety LLC

- Jul 22, 2025

- 5 min read

Updated: Oct 23, 2025

Many industrial refrigeration systems in use today were installed over 20 years ago and likely feature Cornell ammonia pumps for recirculating liquid refrigerant in the refrigeration process. Installers would consult a pump catalog, and at that time, the Cornell ammonia pump was the preferred choice over other options like Buffalo pumps and Durco pumps. Ammonia systems still using Cornell ammonia pumps for liquid recirculation have almost certainly required periodic rebuilding throughout the pump's operational life due to the mechanical shaft seal design (will refer to this mechanical shaft seal as a "seal cartridge" throughout this article). Needing to rebuild an ammonia pump doesn't indicate a poor design; it simply means the pump requires additional inspection and maintenance. Semi-hermetic ammonia pumps, which lack a mechanical shaft seal, have been adopted by many facilities to replace the open drive style pumps that operated for decades.

Why replace a Cornell pump with a semi-hermetic design? The ammonia pump is typically situated beneath a large pressure vessel containing liquid anhydrous ammonia (R717). If the mechanical shaft seal fails, it can lead to an uncontrolled release of liquid ammonia into the atmosphere, which is undesirable for anyone involved. Although the mechanical shaft seal for an ammonia pump is an older design concept, any time we need to control internal components of a closed-loop system, some type of seal is necessary. For example, ammonia isolation valves require a seal (packing) to prevent system contents from escaping into the atmosphere when closing/opening a valve. Similarly, in an ammonia screw compressor, the drive motor acts as the prime mover. A shaft from the screw compressor extends outside the housing, allowing a motor to be coupled, which necessitates a mechanical shaft seal (some screw compressors can be semi-hermetic). Thus, sealing the contents of a closed-loop system from the atmosphere is unavoidable but manageable. The ammonia pump has a high risk of releasing liquid ammonia, prompting many to switch from an open drive design to a semi-hermetic design.

For many facilities, retrofitting a semi-hermetic pump is neither within the budget nor under consideration. Continuing to operate the refrigeration system with a Cornell pump is the sole option, and regular maintenance is unavoidable. Even in 2025, many of us still rely on an instructional YouTube video from the 80s on how to rebuild these Cornell pumps. The procedures are straightforward and similar to rebuilding a water or glycol pump, with the mechanical shaft seal design being quite comparable. In maintaining a Cornell ammonia pump, the seal installation is usually prioritized for thinking it leads to seal longevity and to prevent complete seal failure. While conducting operator training at facilities across the US, when discussing pumps, many operators, both new and experienced, inquire about extending the life of the mechanical shaft seals on these pumps. Many report that their seals only last 6 months to a year and seek advice on installation techniques to prolong seal life. This suggests that those in charge of maintaining the equipment are unaware that regular inspection and maintenance of the seal are essential for prolonging its lifespan. If you install a new Cornell pump seal and don't notice any signs of potential or immediate failure within the first few days of operation, it's likely that the seal was installed correctly. The YouTube video offers steps to guide you in testing your mechanical shaft seal pneumatically on the bench before reinstallation, which helps prevent an immediate release when ammonia is reintroduced into the pump.

Generally, the early failure of a mechanical shaft seal on a Cornell pump is more associated with the pump's operating conditions and oil management than with the techniques used during seal installation.

Key points for extending the seal life on a Cornell pump:

Prevent pump cavitation

Oil management

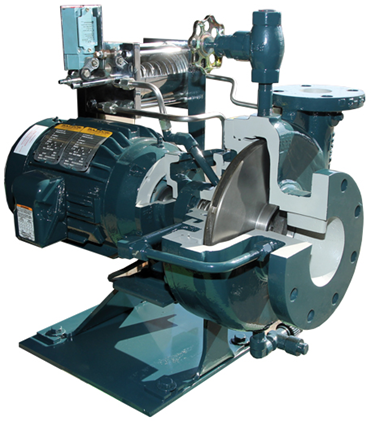

Preventing pump cavitation can significantly reduce unwanted wear on the seal cartridge. When comparing seals of water or glycol pumps to those of ammonia pumps, typically, water or glycol pump seals last much longer than ammonia pump seals, even though the seal designs are practically identical. What makes the difference? Liquid ammonia functions at its saturation point (boiling point), so any pressure changes within the pressure vessel connected to the pump can lead to the formation of more bubbles (vapor) in the liquid refrigerant than intended. The compressors (screw or reciprocating) are responsible for maintaining the pressure inside that vessel, they manage the pressure at the pump's inlet. If the suction pressure of the vessel is not stable, the pump is likely experiencing cavitation to some degree. The pressure from the ammonia pump's outlet is responsible for supplying pressure to the pump's oil reservoir. Cavitation introduces vapor, leading to a decrease in pump pressure. The pump's oil reservoir contains a piston that is pressed by the outlet pressure of the pump (see the Cornell pump cutaway image below). Remember, vapor/gas can be compressed, unlike liquid, which is not compressible. When liquid refrigerant presses against the reservoir piston spring, it can effectively compress the spring and maintain steady oil pressure at the seal cartridge. Proper oil pressure to the seal cartridge is critical for lubrication. Reducing cavitation will in turn increase the seal cartridge longevity. Additionally, excessive cavitation may also harm the ammonia pump impeller, but this article concentrates on prolonging the lifespan of the mechanical shaft seal for a Cornell pump.

Oil management is a frequently neglected aspect of prolonging the lifespan of seals on Cornell ammonia pumps. During our inspections or audits at various facilities, we often discover that oil jugs used for adding oil to Cornell pumps are left open to the atmosphere, improperly sealed, and not stored correctly. On one occasion, we observed a jug left under a recirculator package with compromised insulation, where ice was melting on a hot summer day, the water drops from the ice was splashing directly into the oil jug that was not properly sealed. Most POE oils are hygroscopic, meaning they attract moisture when exposed to air. When adding oil to the reservoir, this is a routine maintenance task for Cornell pumps. Typically, the more often this task is required, the closer the seal is to the end of its useful life. Another common issue is that when oil is added to the reservoir, many fail to bleed air out of the oil jug transfer pump and neglect to bleed air from the reservoir itself using the bleeder screw. If air enters the oil side of the reservoir, it introduces moisture into the oil (all air has moisture in it). Air also compresses, causing the oil to follow the path of least resistance, which likely results in the seal cartridge being deprived of lubrication. Ensuring the correct procedures are followed when adding oil to the reservoir is crucial for the longevity of the seal cartridge.

Another method often chosen to prolong the life of the seal cartridge is to use specialized oils specifically designed for the Cornell pump. Oil manufacturers like Camco Lubricants have created special oil formulas with a seal conditioner to enhance the seal's lifespan compared to other mineral oils available (see the Camco Lubricants catalog product below). Camco oil also has a lower pour point, which helps prevent issues when the pump starts, particularly in lead/lag or standby operations. For comparison, car manufacturers indicate that most engine wear happens during startup when the oil is cold and hasn't yet reached operating temperature. This increased wear during start up also happens with Cornell pumps. Cornell pumps are fitted with a heater element to maintain oil temperature, but using an oil more suitable for cold conditions will further extend the seal cartridge life, especially if the heating system has faults that go unaddressed, which could be another potential failure point for the seal cartridge.

Stay tuned to the MySafety blogs. Reach out to us if you have additional questions or concerns. Our team will be pleased to assist you.

Our community can't grow without you, and we deeply appreciate your support.

Please LIKE, SHARE, and FOLLOW our content on social media platforms.

Join our newsletter mailing list to stay up to date on our latest blogs/articles and information.

KEEP IT COOL & SAFE!

Comments