How Do Ammonia Pumps "Pump"

- MySafety LLC

- Apr 30, 2025

- 3 min read

Updated: May 12, 2025

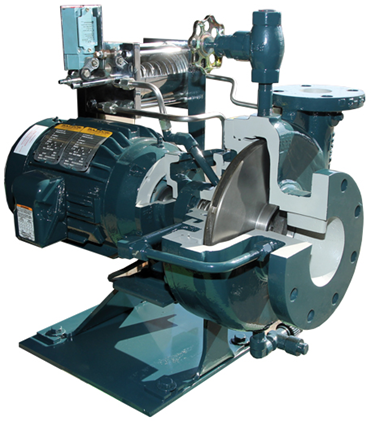

Ammonia Pump(s) play a crucial part in the proper operation of the ammonia refrigeration system. If ammonia pumps are not functioning properly, no liquid refrigerant will be supplied to evaporators and/or heat exchangers. This results in no heat removal from the process. The two most common types of ammonia pumps are centrifugal mechanical shaft seal design and centrifugal semi-hermetic design. Pumps are designed to create a pressure difference so fluid can flow (no pressure difference = no flow). The restriction to flow is what creates pressure. A common misconception is that a pump creates pressure but instead they create flow. This applies to positive displacement pumps (fixed or variable) or centrifugal open design pumps (fixed or variable). The type of fluid that it’s pumping does not matter (oil, water, ammonia, etc.), pumps are creating flow – not pressure. Pressure is a measurement of the resistance to flow. The maximum pressure rise would be at a zero-flow rate – this is when the pump discharge valve is closed. As valves in the system are opened, the flow rate increases and the pressure differential decreases.

Energy Converting starts by delivering electrical energy to the motor and then converting it into mechanical energy. Mechanical energy is coupled to the pump input shaft and is converted into kinetic energy. If using a centrifugal design, the impeller is the beginning point of kinetic energy. When the fluid contacts the volute (impeller housing), this is the first point of kinetic energy being converted into pressure energy.

Pump Head is the measurement of kinetic energy that a pump creates. If you take your water hose at home and shoot it straight into the air, how many feet up does it shoot? The height that the water reaches is called pump head. Pump performance is rated by the head it can produce. It’s all about the feet of liquid that the pump moves.

Suction Head is when the supply inlet to the pump is above the centerline of the pump. This is also known as Net Positive Suction Head (NPSH).

Static Head is the amount of pressure exerted by a column of liquid. Typically, measured in feet of liquid but can be converted to psi. The pressure at the top of a column of liquid is not the same as the pressure at the bottom because of gravity.

Friction Head is the head to overcome all restrictions such as piping, fittings, valves, and fluid characteristics all contribute to friction head. When talking about fluid characteristics, ammonia is considered a Newtonian fluid (non-viscous liquid/gas). Water and gasoline are also categorized as Newtonian fluid.

Pressure Head is when a pump inlet or outlet is connected to a tank that is under some pressure other than 0 psig / 14.7 psia. The pressure in such a tank must be converted to feet of liquid (vacuum reading is still a pressure reading). Even though the pump is not pumping vertically into the air, pumping against a pressurized tank is going to affect flow. The tank pressure being above or below 0 psig changes pump head. This depends on which side of the pump (inlet or outlet) that the pressure is above or below 0 psig.

· Vacuum Pressure Inlet Side = Reduced pump head (less flow)

· Positive Pressure Outlet Side = Reduced pump head (less flow)

· Vacuum Pressure Outlet Side = Increased pump head (more flow)

· Positive Pressure Inlet Side = Increased pump head (more flow)

Stay tuned to the MySafety blogs. Reach out to us if you have additional questions or concerns. Our team will be pleased to assist you.

Our community can't grow without you, and we deeply appreciate your support.

Please LIKE, SHARE, and FOLLOW our content on social media platforms.

Join our newsletter mailing list to stay up to date on our latest blogs/articles and information.

KEEP IT COOL & SAFE!

Comments